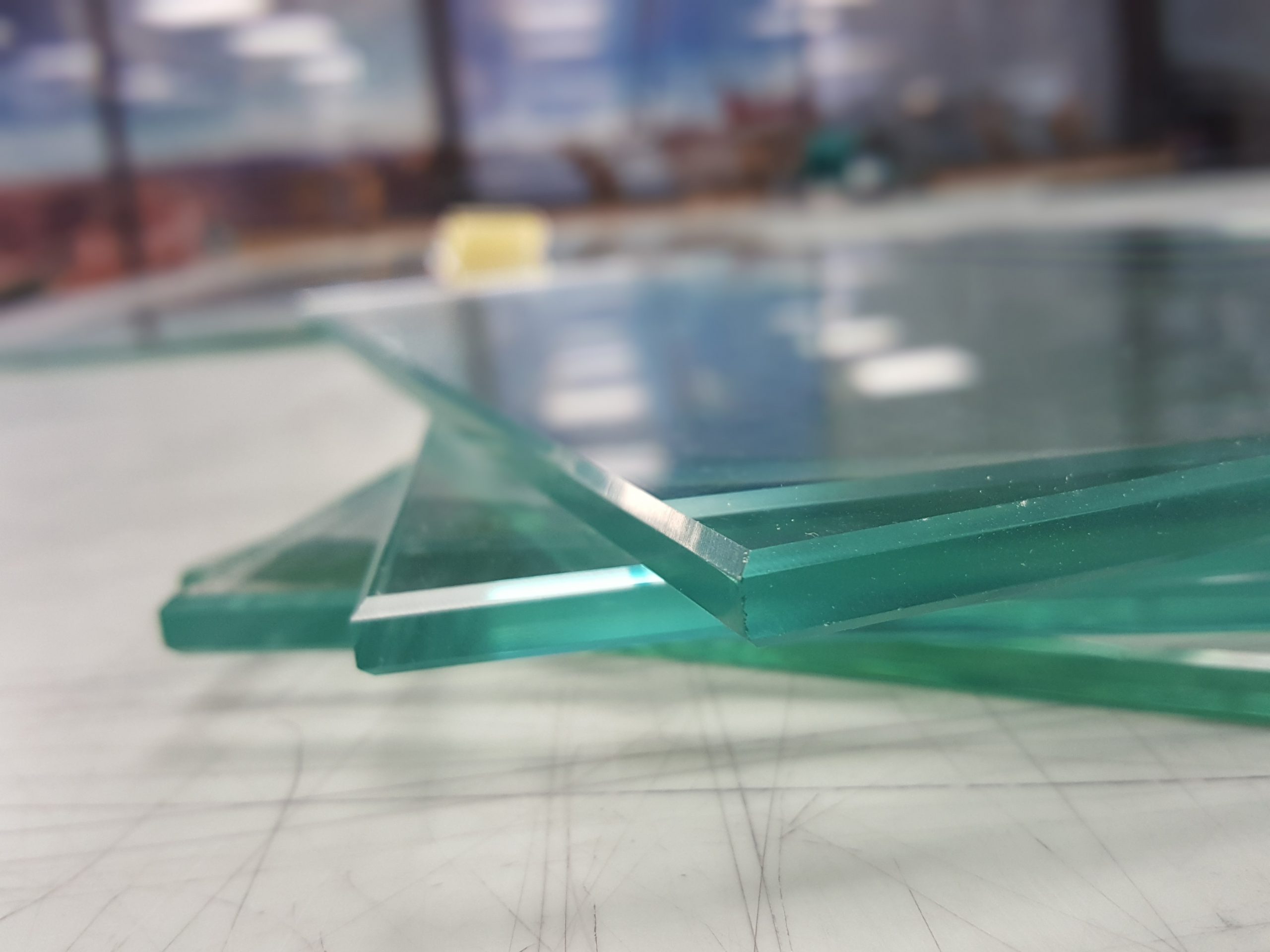

The first step of glass production is to cut the glass from a large sheet into the required size, which leaves a rough edge. We have three distinct methods for edgework to suit the purpose of your glass: Arrised, SLE (Straight Line Edger) and CNC.

Straight Line Edger

Our SLE finish will give your glass edge a 1.3mm bevelled finish with mitred corners, or dubbed corners on request. As the name might imply this edge can only be used for pieces of glass that have only straight edges, for a proper finished edge on a radius corner we would have to use our CNC machines.

Arrised

This type of edge simply uses a dry belt sander to take off the sharp edge. This finish is not very tidy, and is only intended as a method for glass that will be hidden by a frame.