Cutting

The first process after the initial set up and pre production steps at STG is to process the sheets of glass we have delivered to the factory into the shapes the customer requires.

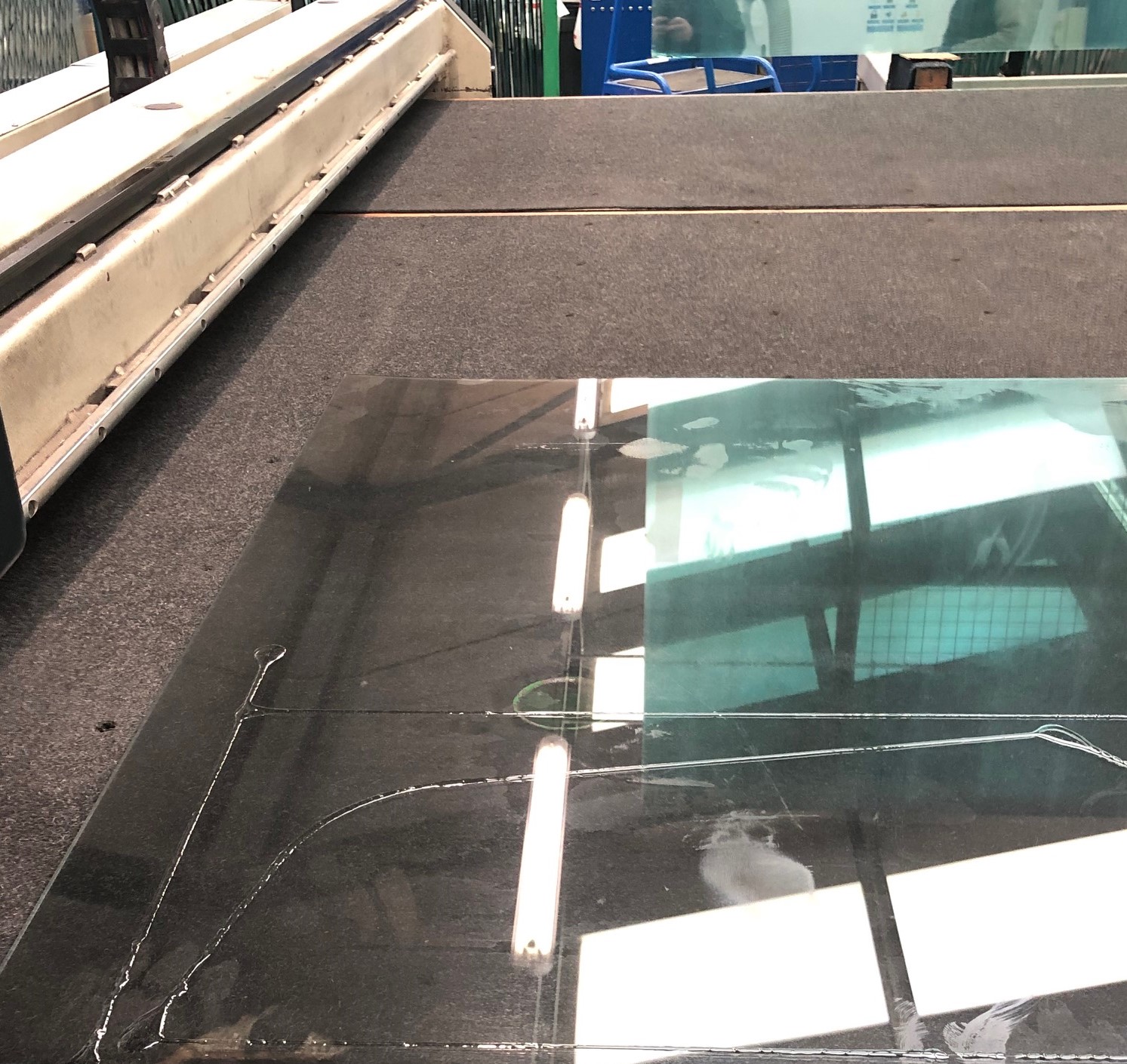

Our glass can arrive at the factory in a variety of sheet sizes, thicknesses and tints. Once stored and stacked into allocated glass shelves, individual sheets are moved via crane to an angular cutting table that cushions the piece of glass on a layer of air in order to allow the glass to be turned when required. The shape of the glass required by the customer is scored into the sheet by a diamond cutting wheel and automated cutting head that maps the shape via CAD drawings loaded in by the operator.

We can cut glass and process glass from 4mm to 25mm thick with the most common varieties of tint being clear, grey and opti-white glass. Float glass in this state after cutting is still very sharp so as a basic finish we provide an arrised edge which is created by running the edge of the glass against two bi-directional sanding belts until the edge is blunt. This method is only recommended if the edge is going to be hidden by a frame as it is less aesthetically pleasing than the other finishing methods we provide.

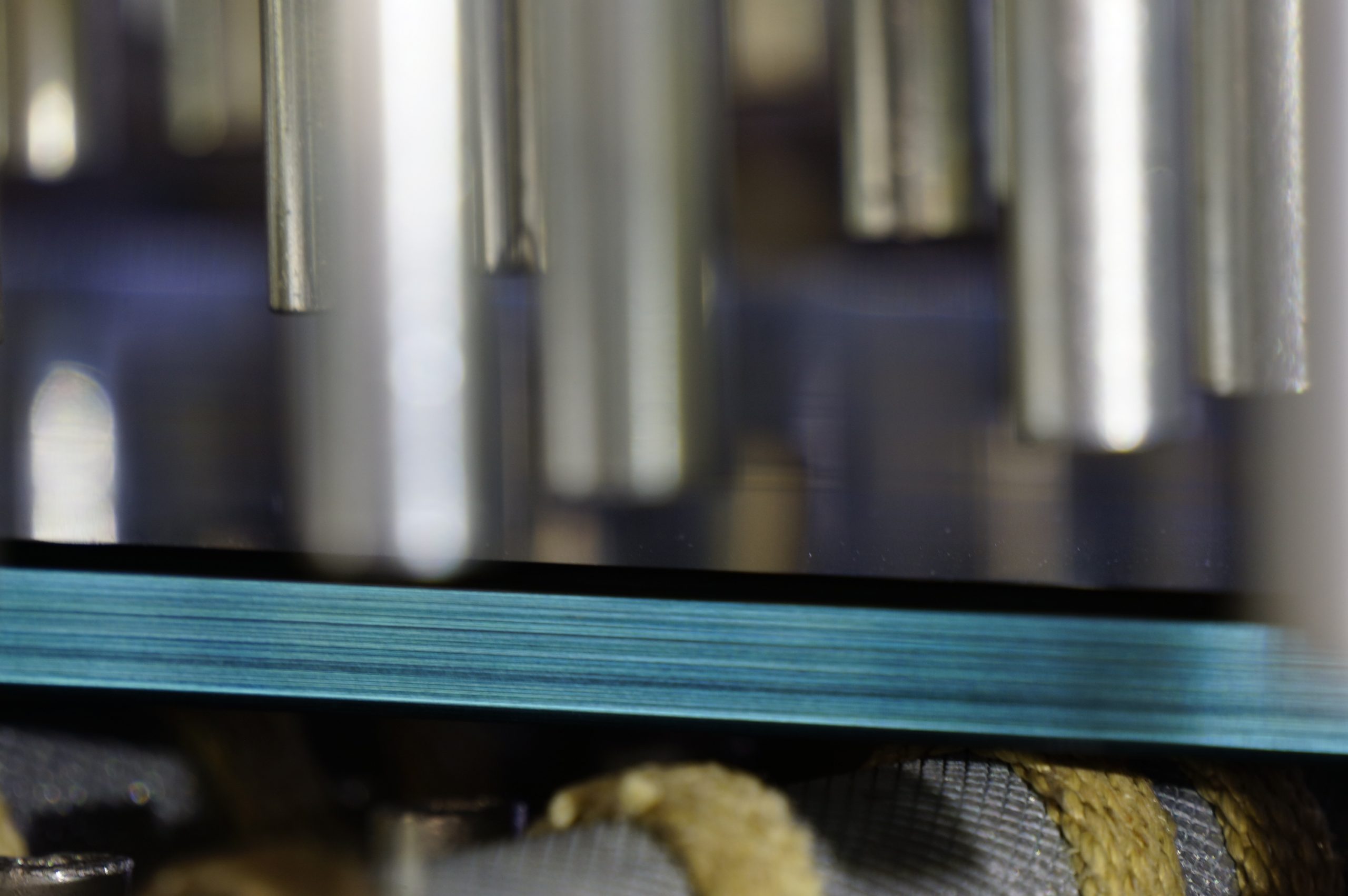

Edging/Polishing

We have two machines at our factory that can create a visually more appealing edge to a pane of glass. Our straight line edger (SLE) is capable of leaving a crisp bevelled edge to a straight edged pane of glass with the bevel measuring at roughly 1.3mm. The bevel is polished and would work well with sliding panes of glass and direct bonded glass where the edge will always be on show.

Our CNC machine is capable of providing a smooth polished finish to the edge of the glass with a similar bevel to the SLE, however the CNC can create this finish on shaped pieces of glass with round corners or complex curves. Drill holes with polished chamfers, cut-outs and notches can all be achieved with this piece of equipment and completed at the same time as the edge polishing.

Minimum Specifications:

Internal radius: 13mm

External radius: 2mm

Printing

Printed designs, such as etch patterns, colour imagery or black borders are printed on the rear face of a piece of glass (unless otherwise stated) with the intent to view them through the glass from the other side. This process is done via a state of the art digital printer that uses ceramic based ink over 7 different channels (CMYKGW and Custom) to print full colour 1440 dpi designs before the toughening process which bonds the design to the glass permanently. The ceramic based ink starts in a liquid form but slowly hardens as it dries to leave a solid ceramic print which has a lower melting point that the face of the glass. When this is toughened the design melts into the face of the glass without losing its complex design integrity and once cooled becomes the new face of the glazing which is UV Proof, highly scratch and weather resistant.

Designs can be made to fit any piece of glass with popular and versatile vector designs being able to stretch or tile without a loss in quality. imagery can also be printed but it requires a decent source file with a high number of megapixels and print ready resolution (300dpi preferred) in order to achieve the best possible output.

File types accepted: pdf, eps, jpeg, bmp, png, tiff, psd

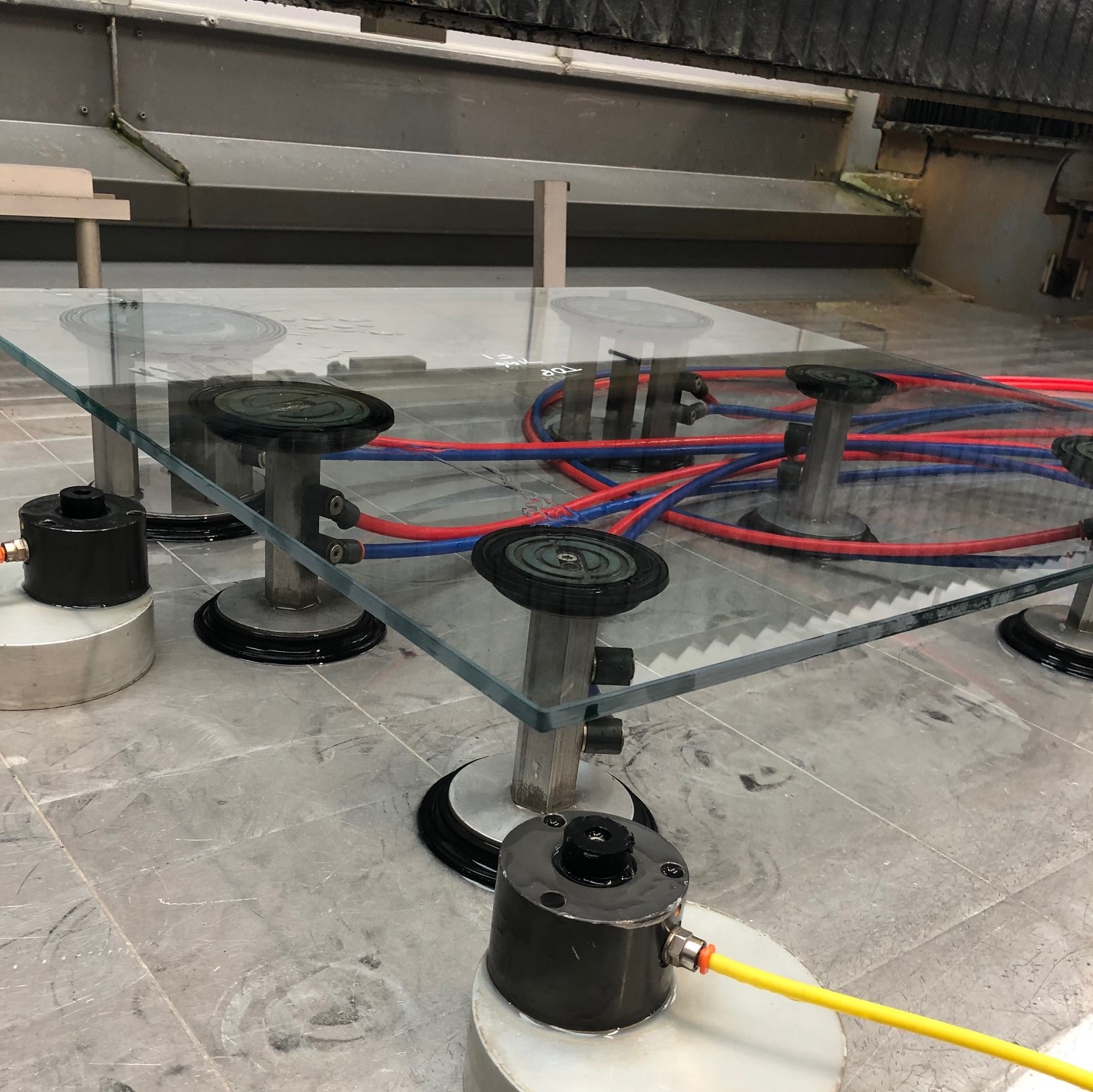

Toughening

Toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. ST Glass uses a thermal toughening process which compresses the outer surfaces of the glass while also placing the inner surfaces into tension.

This process strengthens the glass against surface impacts and pressure while also allowing the glass to crumble into small segments if broken. These small chunks tend to be almost blunt compared to the large jagged shards created from annealed glass, and the likelihood of injury is greatly reduced.

Glass that has been toughened using a thermal or chemical treatment can not be modified (cutting grinding or drilling) as it is the total compressive stress that the final full piece of glass has been placed under that gives it its unbelievable strength. By creating a hole in the glass or changing the edge, the glass will release the pressure rapidly from the newly modified area causing the glass to fracture.

After the process the toughened glass has a greater thermal resistance and has improved flexural and tensile strength, the colour, clarity and chemical composition of the glass remains unchanged. Glass that has been produced in this manner can also be laminated in order to make sure that after receiving an impact the individual shattered pieces stay in place using an anti splinter film that coats the outer surfaces.